DCS Conversion Opportunity

Recently ESC was asked by a client to help them with a decades-old DCS system controlling a process for disposition of explosives. The original system had been adapted on many occasions to provide increased functionality. Documentation of these changes was mostly non-existent. Other issues included the requirement to use outside resources to troubleshoot operational problems, along with poor integration to an existing Emissions Control System and other sub-systems. Uncertainty of replacement part(s) availability and unscheduled downtime had become increasing obstacles for production. It was also desired to provide operations with a better, more intuitive interface to the system.

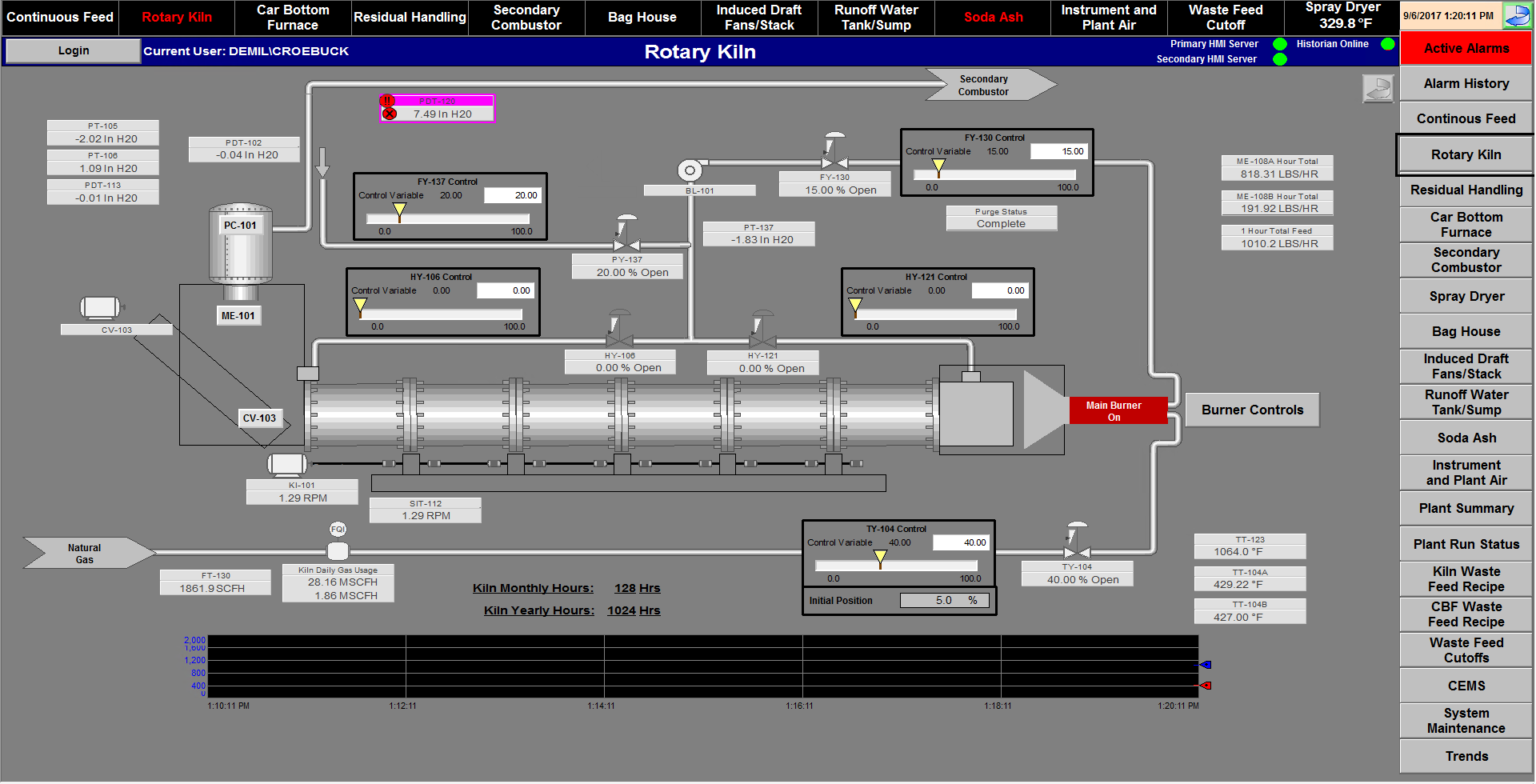

By leveraging ESC’s vast knowledge of process mechanical, electrical, IT/OT, and automation we were able to conceptualize a plan to replace the I/O and DCS controller with an Allen-Bradley ControlLogix PLC/PAC controller connected to new networked and distributed I/O. By rewriting the software and commissioning a brand-new distributed operated interface system, the operators now have much better visibility into the status of the plant. This new system provides all of the functionality of the old, along with powerful diagnostics so that when problems occur, they can be quickly diagnosed and rectified.

All of this was accomplished with minimal downtime. With the use of Rockwell Automation’s PlantPAx Process objects and custom-designed Human Machine Interface, Operators were quick to learn how to effectively operate the new system. Electrical drawings were updated to reflect the new I/O connections providing plant technicians proper documentation for future troubleshooting.

Our client was very happy with the outcome of the project and has asked ESC to complete other projects since commissioning of this system.

As this was a multi-step process, click here for further details.